Seacrets Distilling Company is a bit of a local anomaly. They’re the first distillery to be built in Worcester County since the end of Prohibition in 1933, but they were only just built in 2016. Even more anomalous for a distillery that’s not even two years old, their spirits are highly decorated: All of their flavored vodkas have won awards in varying distillery competitions, while their spiced rum took a silver medal in the American Distillery Institute’s Best in Spiced Rum category.

The praise their spirits have received probably has something to do with the way they’re flavored. Rather than instill their liquors with artificial flavors, the flavoring at Seacrets Distilling is all-natural. Their orange vodka, for example, is flavored with the “meat” and the macerated peels of blood oranges. Even the water they use in their spirits is Culligan water, filtered and free from many of the contaminants of public, city water.

“It’s down to something that you really wouldn’t think is a big deal affecting taste, but it does,” said Jackie Miller, Seacrets Marketing and Advertising Manager. “I think you can really taste the difference.”

***

Cody Miller is the head distiller at Seacrets Distilling. He got his start as a homebrewer, and worked at Burley Oak for the first several years they were open. He says he “was a beer guy for years,” but since learning the ropes of the distillation process, he’s come to prefer distilling over beer brewing.

“You still get to make beer, we’re still brewing, we’re still taking the raw ingredients whether it’s corn or barley or molasses for the rum,” Cody said. “We’re making a beer and then we’re just taking that beer…and we run it through the still, and that’s where we’re taking those flavors. ”

Distilling is a lot like the beer-making process, he says–“just a couple more moves.”

“We’re creating a beer, essentially, and then taking that beer and heating it up and cooking it. If you take a beer and cook it on the stove, you see the vapors rising, so we’re just catching those vapors.”

In December, in the peak of the slow season and when the distillery only offers tours on weekends, I was lucky enough to be given the grand tour of the place by Cody. More on his background, and the scientific ins-and-outs of the distilling process, can be found here.

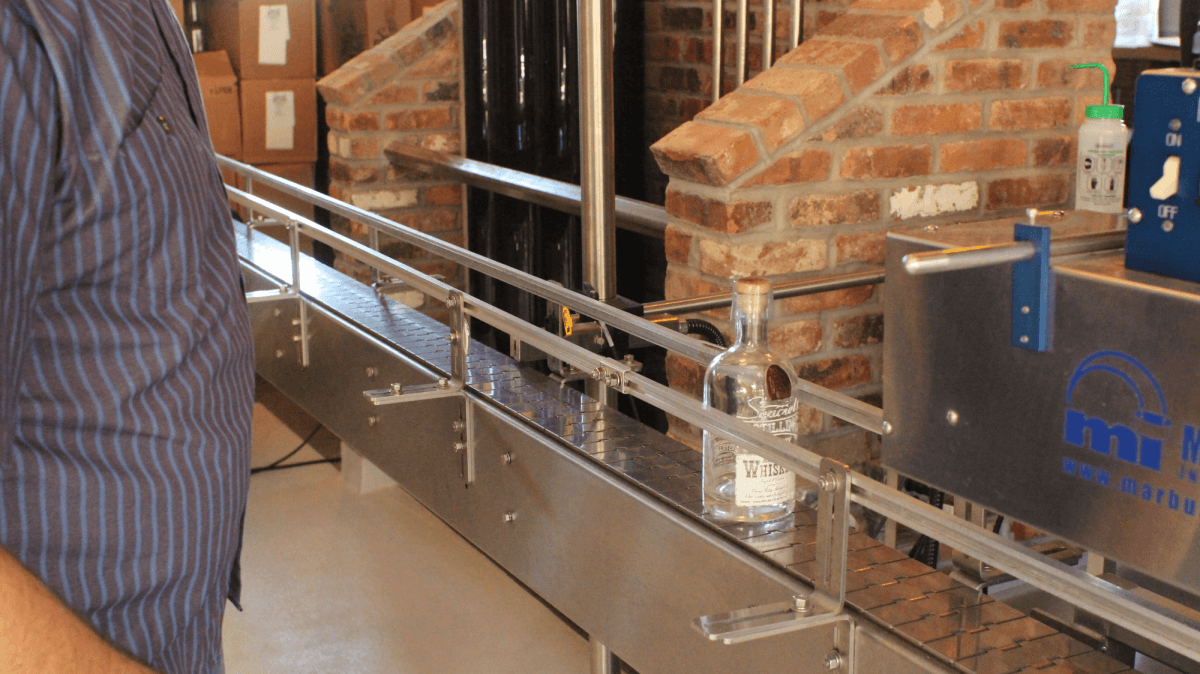

Below is a little virtual tour of Seacrets Distilling Company, and a taste of what you’ll see if you ever decide to take the tour for yourself. Though maybe “taste” is the wrong word–for that, you’ll have to go up to the Speakeasy on the third floor to sample the spirits for yourself.

The craft tour experience

Walking into the distillery is a lot like walking through a time machine and coming out in the mid-1930s, sometime just after the end of Prohibition. Most of the furniture, wall pieces and decorations adorning the building are authentic to that era, and those that aren’t are pretty accurate replicas.

“There’s the craft liquor, but the building is kind of a craft itself—it’s kind of a craft tour experience,” Jackie said.

Take the elevator up to the third floor and the craft tour experience is magnified. After seeing the distilling process at work–more on that below–you’re taken to a convincing shop front of a pharmacy, behind the doors of which is a pseudo-speakeasy.

“What’s cool about this pharmacy, back during Prohibition the only way to get alcohol was through a physician, a dentist or a veterinarian,” Cody said. “You get your prescription, you take it to the pharmacy and you get it filled. Behind some pharmacies were speakeasies, so that’s what we did here.”

The distilling process

Seacrets Distilling is focused on keepin’ it local. The very process starts at local farms, where a portion of the ingredients going into the spirits are grown.

During the process, the “heads, hearts and tails” are cut, depending on the spirit being made.

“A lot of the rail liquors that essentially give you a headache, they keep a lot of “heads” portioned in there,” Cody said. “And that part is the different alcohols in there that are toxic, methanol, acetone, they’ll give you the headaches. People keep ‘em in there because it increases their overall volume. Us, we cut it out completely.”

They strictly collect the hearts–or the pure ethanol–for their vodka. For whiskeys, bourbons and even rums, they go “deeper into the tails side,” collecting flavors that will age well in barrels.

The maceration room is where that blood orange meat is soaked in the vodka. To Jackie, the use of natural fruit rather than artificial flavors is what keeps the alcohol from having a syrup-y sweet taste that’s common in cheap liquors. To Cody, it’s what makes Seacrets Distilling the best distiller around.

“It’s easy just to go out and buy a bottle of orange flavoring and add it to your vodka,” he said. “Take your vodka, make it in a day and you can have an okay vodka. But we’re not for okay, we want to be the best. If it takes two-and-a-half weeks to make one batch of vodka, we’ll just wait it out.”

The taste!

The distillery tour ends in the best way possible: up in the speakeasy, for samples of the spirits. Each guest can sample three spirits while enjoying the atmosphere of the 1930s model saloon and buy a bottle or two if they’re so inclined. The speakeasy, like the distilling room, will double in size with the expansion slated for winter of 2018-19.